Pingel Electric Speed Shifter Save the Day!

Helping The Disabled Ride

By Rogue

10/11/2019

In September of 2018 my son Dale traded in his 2008 Harley Ultra Classic and got a 2019 Harley Street Glide, while putting on break-in miles, a car made an illegal left turn and hit him. The motorcycle was totaled and Dale lost his left foot.

Seven Operations and a year later he got a prosthetic foot. He is currently adjusting to using it.

With the money from the motorcycle insurance company he went to Space Coast Harley-Davidson in Palm Bay, Florida, who had a leftover 2019 Street Glide and gave him a deal he could not refuse.

Two issues that needed to be addressed before he was ready to ride. The shifter and operation of the kickstand needed modifications. I got to ride it to my house and put it on the lift.

It did not take me long to decide that the Electric Speed Shifter made by PINGEL Enterprises was the way to go. I have been using their products since the late ’60s and have always been happy with them.

It is named speed-shifter, and all the people I talked to spoke very highly of it. We weren’t interested in the performance aspect, but just shifting. Hey, the bike is new and needs break-in miles, before speed comes into play.

I should note, that when ordering, pay attention to if the motorcycle has heated grips or not as the handlebar control is a different size for each.

When the kit arrived, I was pleased with the quality of everything.

Next, I did what I consider is a very important part of the job and that was to read the instructions and I suggest you do too.

Part of the instructions say all the components have been tested prior to shipping but it is suggested that the installer (that would be me) bench test the unit. I followed the instructions and did so. Now if there was an issue after I installed it, I would know I did something wrong and it was not a defective part.

Installing The Dual Button Handlebar Controller

I removed the main fuse, the negative battery connection and the fairing because I was also installing other things that required that. On this motorcycle to just install the dual button handlebar control the fairing would normally not be removed.

The controller mounts to the handlebar grip as close to the switch housing as possible. There are very detailed instructions on how to install this, and I recommend following instructions. I did opt to vary them slightly.

There is a part of the grip that holds it in the housing so it will not rotate and part of it needed to be removed for the wire to go through.

I did cut the grip so that the wire would fit But I also bolted the handlebar switch housings together and at the bottom used a file to relieve them to accept the wire, I ran the wires through the switch and the housing making sure I could slide it when everything was tightened. I finished reinstalling the switch and clutch bracket, ran the wire down the handlebar with the one already there and out the bottom of the fairing.

I had already removed the fuel tank so that I had access to the wire tray, again because of doing other work so I opened it and ran the wires inside it. The wires can be run under the tank without doing this if you are careful and use the supplied wire ties. Excess wires can be coiled and hid under the seat.

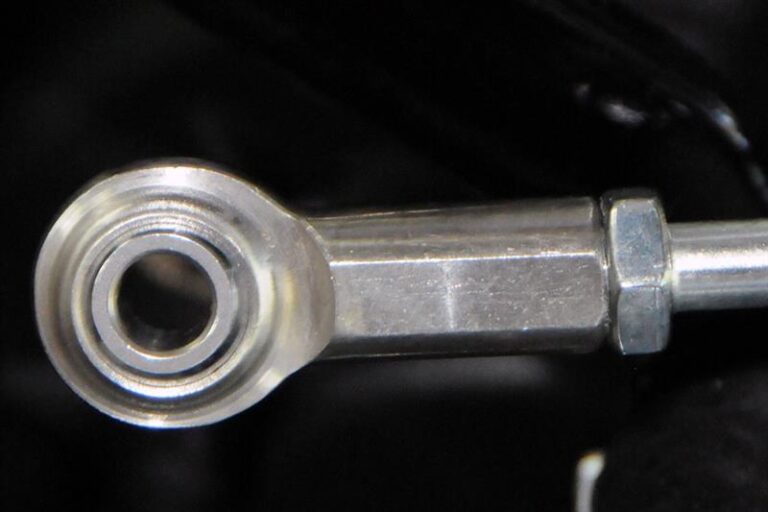

Remove stock shift rod from the stock shift arm lever. Remove the stock ball joint from the end of the shift rod and replace it with the supplied 5/16 rod end and jam nut.

Since this was a new motorcycle there was no wear in any of the shifting parts. If installing on a motorcycle with miles on it follow the instructions pertaining to end play and tightness.

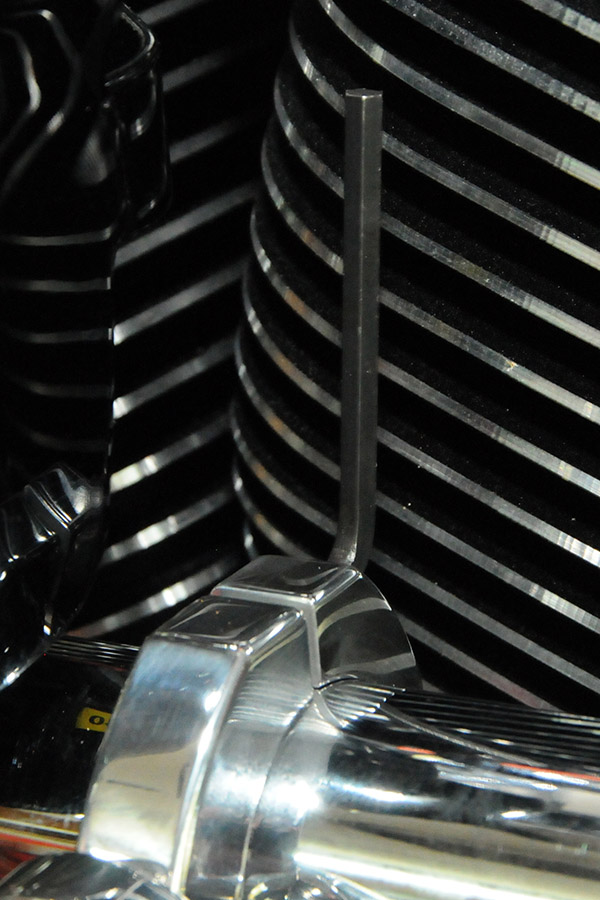

Attach the Pingel shift arm lever on to the shift arm by using the 5/16-24-1 ½ button head cap screw through the 5/16 rod end you just installed on the intermediate shift rod, through the hole of the Pingel shift arm lever and through the stock shift lever. Use the washer and nut and tighten just enough to hold in place. Tighten the #10-32×3/16 set screw with 7-32 Allen wrench. Now tighten the 5/16 nut

INSTALLATION OF ELECTRIC SHIFT CYLINDER

Install the electric shift cylinder onto the shift cylinder support bracket using the Pingel® clamp and (2) ¼-20 x ¾” socket head cap screws. Mount the cylinder in the clamp. Just snug the bolts for now, as adjustment will be needed later. Remove the two top center bolts on the primary cover. While making sure the rod end on the shift cylinder is pointing forward, install the electric shift cylinder support bracket to the primary cover by inserting the ¼-20 x 2” stainless socket head cap screws (apply thread locker) through the stainless washers, through the bracket and into the holes. To adjust the shift cylinder shaft and rod end for no side bind you must retract the rod end and shaft all the way into the shift cylinder and hold in place. Now move the shift peg so the Pingel shift lever bracket rod end hole lines up with the hole in the rod end. Making sure the flat of the rod end is parallel with the flat on the Pingel shift lever bracket without putting left or right pressure (as viewed from above) on the rod end, gauge the gap between the two to determine the correct amount of washer(s) and/or spacer provided. Once this is established apply thread locker to the ¼-20 x 1 bhscs and install it through the rod end of the shift cylinder, the ¼” washer(s) and/or spacer and into the Pingel shift lever bracket on the shift lever. This step is important because if there is any bind in the linkage system the shifter will not work correctly. Before adjusting the shift cylinder front to back make sure the motorcycle transmission is in neutral. While holding onto the electric shift cylinder housing, loosen the two screws on the clamp.

Now find the groove in the center of the length of the travel of the cylinder shaft. Adjust the cylinder housing front or back so the mark on the shaft is right at the plastic bushing located on the end of the cylinder housing.

With the shift cylinder in the correct position, tighten the two bolts of the Pingel® clamp. Route the electric cable from the electric shift cylinder back to the control module. I installed a clamp that I could route the wire through before continuing to the battery area.

Pay Attention To The Instructions On Connecting Wires To Modules And Then To Wires On The Motorcycle.

There are two modules and they are mounted under the seat using supplied Velcro pads. The Control Module is used for the shifting and the Electronic Engine Kill Module interrupts the ignition when shifting which allows the rider to shift clutchless

Testing The Kill Module

Make sure the electric shift cylinder wire is disconnected from the module. Take note of the positions of the dipswitches on the electronic kill module. Turn all of them to the off position. Pull in the clutch and hold it in until the end of the test. Make sure motorcycle is in neutral and start the engine. Arm the system by depressing one of the buttons for 5 seconds, this will arm the system. Rev the engine to 1500-2000 rpm and hold it there. Press either button and watch for a 150-200 drop in rpm.

The system performed letting me know that all the wires were connected correctly. The engine was shut off and the shift cylinder wire was installed to the module. The dipswitches on the kill module were then returned to the position they were in before the test.

Using a motorcycle frame lifting jack the motorcycle rear wheel was raised so it no longer was on the lift table. The motorcycle was started, the system charged and went through the gears using the buttons. Everything worked.

The motorcycle was removed from the lift and I rode it on the street for a final test.

Then it was Dale’s turn. He had not ridden in over a year. Down the road he went and when he returned, he had a smile on his face. Thank You Pingel for helping get my son back on the road and I am sure many other people who are having issues shifting their motorcycle.

The motorcycle was put back on the lift and let it cool off and blue thread lock was put on the cylinder clamp bolts, they were removed one at a time to make sure we did not lose our cylinder adjustment.

We waited a day and then went on an 80-mile ride together. Getting use to the shifting, stopping and going Dale did well and I am confident he will continue to do so.

Some options I liked is that you can still use the clutch to shift if you like and not hurt anything.

In the interest of safety this is the recommended starting procedure: To arm the electric shifter, make sure the motorcycle is in neutral and pull in the clutch lever, then start the engine. With the clutch lever pulled in push either button on the handlebar control and hold it for five seconds; now release the clutch lever slowly (in case the motorcycle is accidentally in gear). The system is now turned on and will shift when either button is pressed. When the key is turned off, the power to the control module is disengaged so this procedure must be performed every time the motorcycle is turned back on. Pull in clutch and check shifter movement by pushing either button on the handlebar control. It will only be necessary to use the clutch when starting, stopping and finding neutral. Upshifting and downshifting will not require the use of the clutch. The operator can use the clutch manually without harm to any components, especially during downshifting to avoid “chirping” the rear tire.

You can find out more about this and other great products by Pingel by going to www.pingelonline.com